The largest work envelope (2655mm) of the R2000iB series, combined with the flexibility make the Fanuc R-2000iB 165F a valuable addition to Fanuc robotics. This six-axis industrial robot offers high performance and the ability to handle medium payloads(Max165kg). The R-2000iA 165F features high reliability and maintainability, along with the R-J3iC/R-30iA robot control system.

The versatility of the Fanuc R2000iB-165F has a slim profile design and the route of the process cables through the arm. The counterweights were also removed to increase the overall workspace. The easy coupling wrist is ideal for working in small spaces, providing greater performance in the processes of material handling, spot welding and dispensing.

Mechanical features

- Large work envelope with ability to reach overhead and behind

- Slim profile design

- RV reducers for all axis

- Elimination of counterweight increases available workspace.

- Process/applications cables routed through the arm

- No motors at wrist

Coupled with the state of the art R-30iA controller.

R-30iA features

The R-30iA controller needs less than 1 minute to start (and even less with the basic software only). In case of power failure:

Robot program restarts much quicker than with any PC-based program (non-Windows operating system).

The resume hotstart function allows restarting safely and continuing production after power failure: no need to re-do the whole movement.

Unique resume tolerance check: in case of any program interruption, the robot automatically memorises its position before failure. When the program continues, it checks whether the robot has been moved outside of a preset tolerance. This avoids unexpected movements and collisions.

Increased up-time (robot availability)

VIBRATION CONTROL

Thanks to enhanced hardware and software capacities, the R-30iA controller offers much better robot vibration control. This greatly reduces the robot’s acceleration and deceleration times, leading to reduced cycle times.

WIDE RANGE OF CONNECTIONS (USB2), PCMCIA INTERFACE...

The R-30iA controller has an USB interface in the front panel and a PCMCIA interface inside of the control cabinet

This allows fast and economical back-ups and restore of data and programs.

General features

- Number of axis: 6

- Max. payload: 165 Kg

- Maximum Reach: 2650 mm

- Repeatability: 0.2 mm

- Controller: RJ3iC-R30iA

Robot motion speed

- Axis 1: 110º/s

- Axis 2: 110º/s

- Axis 3: 110º/s

- Axis 4: 150º/s

- Axis 5: 150º/s

- Axis 6: 220º/s

Movimiento de rango

- Axis 1: ± 180°

- Axis 2: + 75°- 60°

- Axis 3: + 230°-132°

- Axis 4: ± 360°

- Axis 5: ± 125°

- Axis 6: ± ± 360°

Robot Applications

- General industrial applications

- Spotwelding and general assembly

- Part transfer

- Material removal

- Dispensing

- Machine loading

- Arc welding

Applications

Arc welding , Spotwelding , Press tending , Palletising , Loading and unloading of parts , Handling of parts , Measurement , Plasma cutting

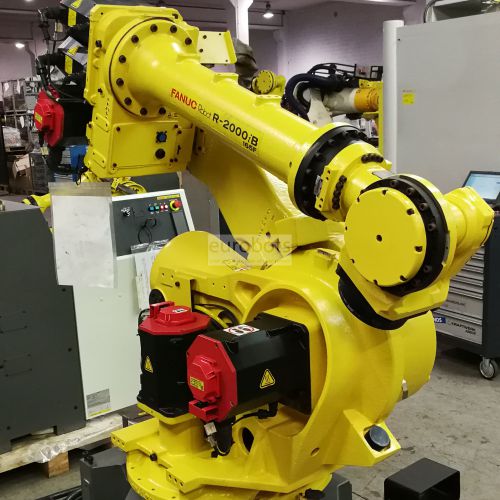

Pictures

Videos

Diagrams