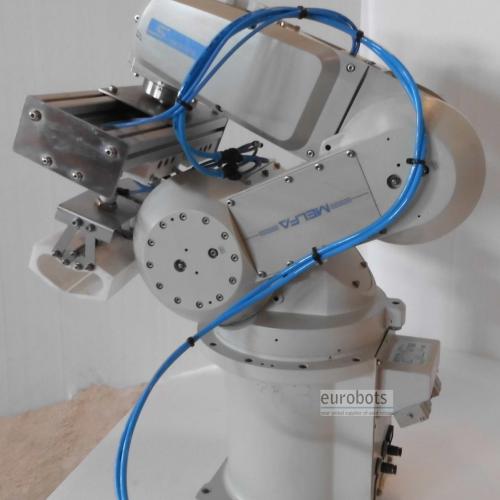

Models RV-3S

This model has been designed to be fast, compact and easy to use

High speed robot, it's the fastest Mitsubishi robot in his category (5,3 m/s), but it's also extremely accurate can be used with a positioning repeatability of ± 0,02 mm. So your cycles would be faster without loosing accuracy.

Flexibility

What can be called a strong robot and flexible robot. It's able to work in hard environment (IP65) because the rotating joints and reduction gears are sealed within the motor's hollow structure.

Three different type of connection : Ethernet, Profibus and CC-Link.

88 different possible program with up to 5000 program steps and 2500 teaching points.

Payload of 3 Kg gives the chance to install different type of tools.

Reduction of the space needed for the robot thaks to the motor and gear installed directly on the arms.

High precision grade

Typically robot arm will stop at an undefined point, instead the RV-3S series will continue its travel to its final position providing customers with trouble free operation. All axes have their own brake so the robot will maintain position in any situation.

The robot is also able to detect different work pieces and to find the exact location. This ensure 100% accurate positioning in any case.

Drive System: AC servo motor (brakes for all axis)

Position detection method: Absolute encoder

Arm lenght:

- 641 mm model RV-3SJB

Payload: 3 kg

Operating range in º:

Axis 1: 340 (+-170)

Axis 2: 227 (-92 to +135)

Axis 3: 290 (+160 to -130)

Axis 4: ---------------

Axis 5: 240 (+-120)

Axis 6: 720 (+-360)

Maximun speed in degrees/sec:

Axis 1: 250

Axis 2: 187

Axis 3: 250

Axis 4: ---

Axis 5: 412

Axis 6: 660

Maximum composite speed (mm/sec): 5300

Average cycle time in sec: 0,6/0,7

Position repeatibility: +-0,02 mm

Weight: 33 kg

Drive System: AC servo motor (brakes for all axis)

Position detection method: Absolute encoder

Arm lenght:

- 641 mm model RV-3SJB

- Payload: 3 kg

Operating range in º:

- Axis 1: 340 (+-170)

- Axis 2: 227 (-92 to +135)

- Axis 3: 290 (+160 to -130)

- Axis 4: ---------------

- Axis 5: 240 (+-120)

- Axis 6: 720 (+-360)

Maximun speed in degrees/sec:

- Axis 1: 250

- Axis 2: 187

- Axis 3: 250

- Axis 4: ---

- Axis 5: 412

- Axis 6: 660

Maximum composite speed (mm/sec): 5300

Average cycle time in sec: 0,6/0,7

Position repeatibility: +-0,02 mm

Weight: 33 kg

Applications

Arc welding , Spotwelding , Palletising , Loading and unloading of parts , Handling of parts , Assembly of parts , Laser cutting

Pictures

Diagrams