Year 2001. Equipped with the versatile RJ3 controller.

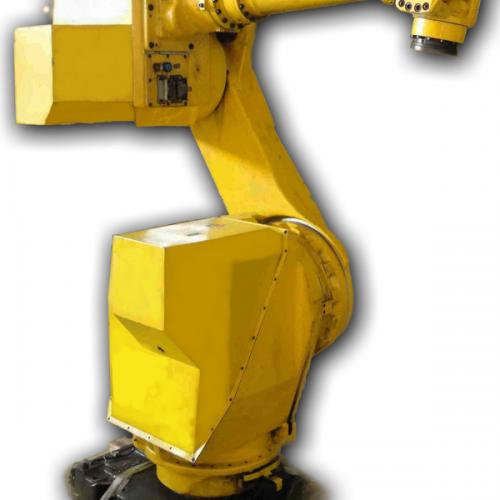

The Fanuc M-710 is a six-axis, modular construction, electric servo -driven robot.

Developed for a variety of manufacturing and system processes, the innovative design of the M-710i robot provides an extremely large working envelope without requiring significant floor space.

The Fanuc M710 is engineered for high speed, application flexibility, and repeatability. They are capable of delivering repeatable precision and unparalleled performance. Floor, invert, wall, shelf, and angle mounting allows the M710 versatility when unusual workpiece access is required. The M710i features an independently tested and certified cleanroom option that exceeds Class 100 cleanliness requirements. An optional sever dust and liquid protection package allows the M-710i and the M-710iW to operate in a variety of harsh environments.

Features:

• The fastest motion speed in this robot class

• Shortened time cycle is supported by introducing advanced

motion control technology (turbo move, vibration control...)

• Heavy wrist payload

• Quick and smooth acceleration / deceleration

• High wrist allowable moment

• Work envelope that works close into the robot

• Water proof of J3 arm and wrist

• Water proof of the whole robot

by severe dust/liquid protection package

The robot can be installed on the floor or wall, suspended from the ceiling or inclined at any angle

By Work Envelope that works close into the robot and flexible motion with flip over, peripheral equipment can be installed under high-density conditions and total system can be built in compact

The advanced technology of the Fanuc R-J3 controller makes it a proven, reliable third generation controller. The open architecture features and process capability improve application and motion performance while simplifying system integration. Fanuc's unique plug-in option allows flexibility for applying specific configurations.

Specifications:

* 32-bit dual processor architecture (separate motion and communication) with real-time clock/calendar

* Built-in Ethernet (10BaseT)

* FTP: allows simple file transfers to a variety of host platforms

* Ethernet Controller Backup/ Restore: provides backup and/or restore of the robot Controller memory image

* Three RS-232 ports (one can be configured as RS-422)

* Teach Pendant: Back-lit LCD, multi-function

Robot Info:

* Maximum Load of Robot: 45 Kg.

* Number of axis: 6

* Maximum Reach: 1706 mm.

* Repeatability: 0,15 mm.

* Controller:RJ3

Robot Motion Speed:

* Axis 1: 160º/seg

* Axis 2: 120º/seg

* Axis 3: 150º/seg

* Axis 4: 240º/seg

* Axis 5: 240º/seg

* Axis 6: 340º/seg

Axis motion ranges

* Axis 1: 320/360º

* Axis 2: 260º

* Axis 3: 420º

* Axis 4: 540º

* Axis 5: 250º

* Axis 6: 720º

アプリケーション

アーク溶接 , パレタイズ , ペインティング , 部品のロードとアンロード , 機械加工 , 部品の取り扱い , 研磨 , 部品の組み立て , 接着-接着剤による接着

写真

ビデオ

設計図