Expanding on the safety, efficiency, flexibility, and user-friendliness of the CR series, the CR20A introduces a breakthrough in payload capacity, allowing for a maximum payload of 20 kg. This significant increase opens up a broader range of applications for collaborative robots. With a generous working radius of 1,700 mm, the CR20A is well-equipped to handle heavy-duty tasks such as picking, packing, palletizing, and welding in industries like automotive, home appliances, logistics, and metal processing.

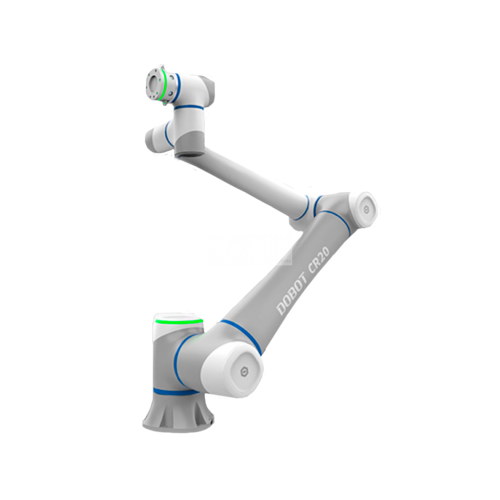

One notable feature of the CR20A is its industry-first dual-channel end effector design, enabling direct connection to multiple end tools. Additionally, it incorporates a visual status indicator located at the base, providing intuitive recognition of the operating status.

With its advanced motion control algorithm, the CR20A ensures stable operation and reduces residual vibrations by 50% during high-speed emergency stops. It supports Profinet and Ethernet/IP communication protocols, facilitating seamless connectivity with PLC systems. Furthermore, it boasts 24 digital IO ports with outstanding support for PNP and NPN switching, simplifying the expansion of applications.

Both the robot body and control box of the CR20A meet a high IP54 protection level. In the event of overload, the robot automatically triggers an alarm. The CR20A also incorporates an innovative electromagnetic brake protection mechanism, reducing the drop distance of the end tool in case of power failure.

The device is designed with user-friendly features with the goal to be a plug and play design, enabling swift deployment using various accessories available in our ecosystem. It offers multiple programming options, including a graphical interface (like scratch), scripting using programming languages (LUA) or API(C, C#, Python, Kotlin...), and the ability to teach the robot by manually moving it. This makes it accessible to users with different levels of expertise.

In addition, it can be controlled with smartphones, tablets, and computers.

| Weight | 70 kg | |

| Maximum Payload | 20 kg | |

| Working Radius | 1,700 mm | |

| Maximum Speed of TCP | 2,000 mm/s | |

| Maximum Joint Speed | J1 ~ J2 | 120° /s |

| J3 | 150° /s | |

| J4 ~ J6 | 180° /s | |

| Range of Motion | J1/J2/J4/J5/J6 | ±360° |

| J3 | ±165° | |

| I/O Ports | Power | 24V, Rated 2A, Max 3A |

| Ports | 2 connectors, RS485/AI, 2 x DO, 2 x DI | |

| Repeatability | ±0.1 mm | |

| IP Rating | IP54 | |

| Noise | ≤ 70 dB | |

| Working Environment | 0° ~ 50° C | |

| Installation Orientation | Upright | |

| Cable Length to Controller | 6 m | |

| Materials | Carbon steel, aluminum alloy, ABS plastic | |

Applications

Press tending , Palletising , Loading and unloading of parts , Handling of parts , Polishing , Assembly of parts , Advanced Manufacturing , Education

Pictures

Videos

Diagrams